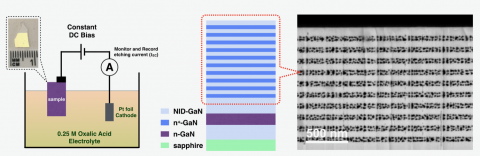

Using a simple electrochemical technique we can create nanoscale porosity in nitride structures, which can be used to change the material's properties in a number of ways. We have demonstrated highly reflective Distributed Bragg Reflectors (DBRs) by creating layers of porous and non-porous material. The etch responds differently to the material depending on its doping density, so a high degree of control is possible through the material growth of the structure to control the doping density of each layer. What's more, the parameters of the etch process can also be used to control the morphology of the pores and which layers etch.

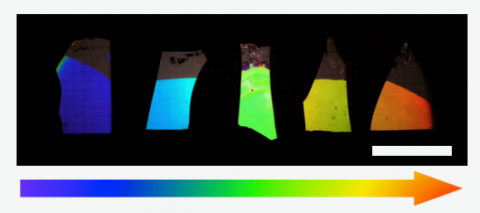

Building on our work on distributed Bragg reflectors, we are now exploring a range of potential applications of porous nitrides. We spun out a company, Porotech, to exploit our porosification technology, and we are helping them to develop porous structures which allow strain relaxation in green, amber and red nitride light emitting diodes (LEDs). this should enable these longer wavelength devices to be more efficient, and is particularly important for microLEDs for display applications. We're also exploring porous nitrides for use in quantum light sources and sensors. Underpinning all this are our studies linking the fundamental structure and properties of porous nitride materials, exploiting expertise in microscopy and microanalysis. The porous nitrides also provide an exciting opportunity for the creation of composites of nitrides and other materials, via infiltration of a range of species into the pores, opening up potential for multifunction materials, combining the optoelectronic and piezoelectric properties of the nitrides with materials which exhibit ferromagnetism, ferroelectricity or other functionalities.